Safety instructions

Take care of yourself!

- Please read user manual carefully before using the instrument.

- Do not use the device if there is visible damage.

- Repair and maintenance of the device can be done only by a qualified specialist of the service center.

- Before connecting the instrument to the electrical network, observe all known precautions, and make sure that the grounding system is to avoid electric shock.

- Use only those accessories that are intended for use with this device.

- While working, do not touch the metal parts near the tip of the soldering iron.

- After completion of the work, it is necessary to install the soldering gun in the regular holder of the soldering gun.

Setting the temperature

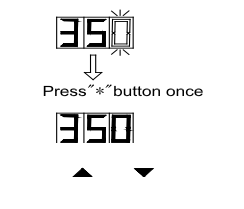

Temperature rising:

Don’t press «*» knob, and press «▲» knob directly. If so, the setting temperature will raise 1°C and the display window will display the set temperature. When loosen the «▲» knob, the display window will delay to display the set temperature about 2 seconds. If within 2 seconds, press the «▲» knob again, the setting temperature will raise 1°C again. If press the «▲» knob and not loosen at least 1 second, the setting temperature will rise rapidly. Till the needed temperature reaches, then loose the «▲» knob.

Temperature dropping:

Don’t press «*» knob, and press «▼» knob directly. If so, the setting temperature will drop 1°C and the display window will display the set temperature. When loose the «▼» knob, the display window will delay to display the set temperature about 2s. If 2 seconds later, press the «▼» knob again, the setting temperature will drop 1°C again. If press the «▼» knob and not loose at least 1 second, the setting temperature will drop rapidly. Till the needed temperature reaches, then loose the «▼» knob.

Parameters Setting

The station has the following working parameters. If you want to set parameters, you must input right password. Setting parameters as follows:

Password Setting

The initial password in station’s memory is «000». The setting temperature is admitted in this status. If need to restrict the setting temperature, the password must be changed and turn off the unit, then turn on.

A. Enter into password setting:

1. Turn off the power switch, Press and hold the «▲» and «▼» buttons simultaneously, then turn on the power switch.

2. Continue holding down the «▲» and «▼» buttons until the display shows  .

.

3. When the LCD shows  , the station is in parameter-setting mode.

, the station is in parameter-setting mode.

B. Input previous password:

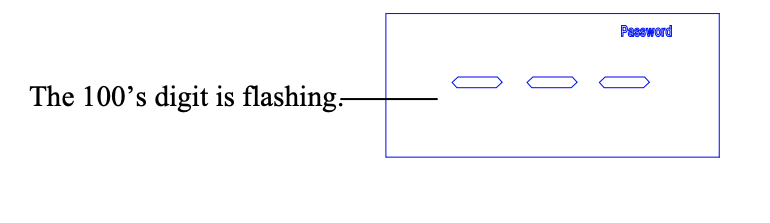

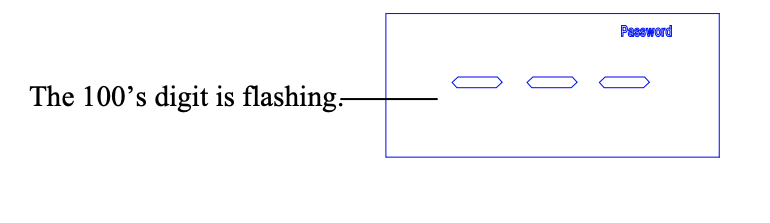

Press the «*» button, the LCD shows  and Password typeface, and the leftmost digit (the 100’s digit) in the LCD will flash. This indicates the station is in password setting mode and the 100’s digit can be adjusted. Use the «▲» and «▼» button to change displayed value. Set the password value in the same way described in «Input calibration temperature».

and Password typeface, and the leftmost digit (the 100’s digit) in the LCD will flash. This indicates the station is in password setting mode and the 100’s digit can be adjusted. Use the «▲» and «▼» button to change displayed value. Set the password value in the same way described in «Input calibration temperature».

After selecting the password of three digit, press the «*» button.

C. The input password is error:

If the station enters into normal work state after display window shows the current setting temperature for two seconds, this indicates the input password is error, and the temperature setting can’t be done.

D. The input password is correct:

If the display window  , this indicates the password of input is correct. After displaying about 4 seconds, the station comes into normal work state, and the temperature setting and parameter setting will be admitted.

, this indicates the password of input is correct. After displaying about 4 seconds, the station comes into normal work state, and the temperature setting and parameter setting will be admitted.

E. Input new password:

When display window is showing , press the «*» button, and shows

, press the «*» button, and shows  , it indicates the station comes into inputting new password state. Press «▲» and «▼» buttons to change displayed value. See «Input calibration temperature».

, it indicates the station comes into inputting new password state. Press «▲» and «▼» buttons to change displayed value. See «Input calibration temperature».

F. Repeat the new password:

When three digits are selected, press «*» button, the display window shows  , again. Now input the new password once again. Repeat the same steps. If the latest two passwords are not the same, pressing «*» button, and the display window shows

, again. Now input the new password once again. Repeat the same steps. If the latest two passwords are not the same, pressing «*» button, and the display window shows  , it needs to rewrite new password. (See the last 8~9 step). The changing of password is successful until the latest two passwords are the same.

, it needs to rewrite new password. (See the last 8~9 step). The changing of password is successful until the latest two passwords are the same.

Note: The word of password is 0 to 9, ten figures. If not, the inputting password is invalid.

Working Mode Setting

1. When the display window shows  , press «▲» and «▼» buttons simultaneously, then the display shows

, press «▲» and «▼» buttons simultaneously, then the display shows  . This indicates the unit comes into working mode setting state, and pressing «▲» or «▼» button will change displayed value as shown below:

. This indicates the unit comes into working mode setting state, and pressing «▲» or «▼» button will change displayed value as shown below:

→ 00 ↔ 01 ↔ 02 ↔ 03 ↔ 04 ↔ 05 ←

→ 10 ↔ 11 ↔ 12 ↔ 13 ↔ 14 ↔ 15 ←

When 10 to 15 are shown among the above values, LCD will display  , this indicates that this working mode has alarm function.

, this indicates that this working mode has alarm function.

2. After selecting the working mode, press «*» button. The working mode is stored into the internal memory. Please refer to the «Working Mode Table» for the meaning of the digit displayed.

Note: «X» represents the original working mode digit.

Working Modes:

|

Working Mode

|

Tip Type

|

Temperature Range

|

Alarm Function

|

Remark

|

|

00

|

Small TIP

|

200°C~480°C

|

Yes

|

In the working mode,  is an alarming mark. is an alarming mark.

Among 10-15 working mode, there is alarm function.

|

|

10

|

No

|

|

01

|

Middle TIP

|

200°C~480°C

|

Yes

|

|

11

|

No

|

|

02

|

Large TIP

|

200°C~480°C

|

Yes

|

|

12

|

No

|

|

03

|

Small TIP

|

50°C~600°C

|

Yes

|

|

13

|

No

|

|

04

|

Middle TIP

|

50°C~600°C

|

Yes

|

|

14

|

No

|

|

05

|

Large TIP

|

50°C~600°C

|

Yes

|

|

15

|

No

|

Up and Down Limited Temperature Setting

1. The station can set upper and bottom limit of temperature value, when tip’s temperature is out of this range, the station can give an alarm (Need to set a working mode with alarm function).

2. After pressing «*» button to store the set working mode, LCD display «up temp», this indicates that the station enter into up temperature setting mode. Press «▲» and «▼» buttons to select the desired value and press «*» button to select the digit bit. After setting, press «*» button to store it. Method of setting value is the same as «Input calibration temperature».

3. When LCD display «down temp», this indicates that the station comes into down temperature setting mode. Press «▲» and «▼» button to select the desired value and press «*» button to select the digit bit. After setting, press «*» button to store it. Method of setting value is the same as «Input calibration temperature».

Switching-off Time Setting

1. If the station isn’t resumed in the set time after it comes into sleep state, the power supply will be shut off automatically, and the LCD will not show anything, the station stop working. Turn on power switch to resume working.

2. After pressing «*» button to store the sleeping time, LCD display «OFF TIME». This indicates that the station comes into auto switching off time setting mode. Press «▲» and «▼» button to select the desired value and press «*» button to select the digit bit. After setting, press «*» button to store it. Method of setting value is the same as «INPUT CALIBRATION TEMPERATURE».

Note:

- The set value represents off time and unit is minute.

- The range of off time is between 00 and 99 minutes.

- The station first comes into sleep state and then comes into off state, so the off time should be more than sleep time, otherwise, the station will be turned off immediately after it comes into sleep.

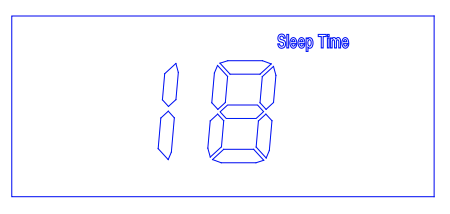

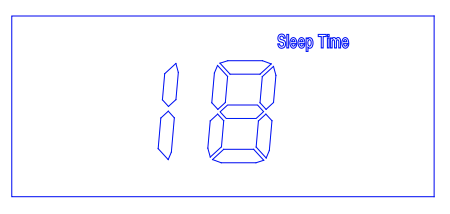

Sleep Time Setting

1. When not operating the station during a certain period of time (the sleep time is more than 00), station will come into sleep state. When the station is in sleep mode, the tip temperature will decrease to 200°C (if the set temperature is more than or equal to 200°C) or 50°C (if the set temperature is less than 200°C) and remain the temperature until resuming the station.

To resume soldering, there are several ways as follows:

- Turn the power switch "OFF", then "ON".

- Press "*" button.

- Take up the iron-handle.

2. After pressing "*" button to store the set parameter, LCD display "sleep time". This indicates that the station comes into sleep time setting mode. Press "▲" and "▼" button to select the desired value and press "*" button to select the digit bit. After setting, press "*" button to store it. Method of setting value is the same as "Input calibration temperature".

Note:

- The set value is sleep time and the unit is minute.

- The range of sleep time is between 00 and 99 minutes, when the sleep time is 00, the station will not sleep.

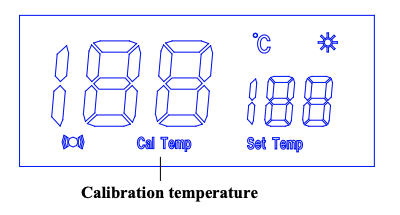

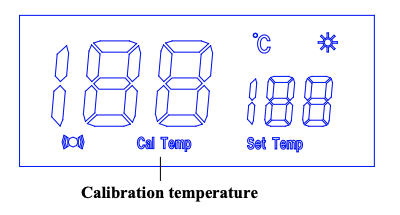

Calibrating the temperature

The soldering iron should be recalibrated after changing the iron, or replacing the heating element or tip. The unit adopts digital calibration mode and the revision value is inputted by pressing button, make the adjustment easily. Method of recalibrating temperature: Use the thermometer to calibrate it, and it is precise comparatively.

Calibrate by using thermometer:

1. Set the unit’s temperature to a certain value.

2. When the temperature stabilizes, measure the tip’s temperature with thermometer and write down the reading.

Press «*» button not loose and press the «▲» and «▼» button simultaneously, the soldering station enters into calibrating temperature mode and LCD display «Cal Temp».

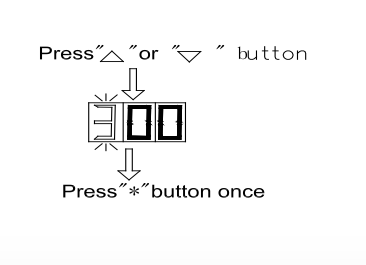

3. At the moment, the 100’s digit in the screen is flashing. Press the «▲» and «▼» button to select the value. The value you select is 100’s digit of the reading and after selecting, press «*» button.

4. Now, the tens digit in the screen is flashing. Press the «▲» and «▼» button to select the value. The value you select is tens digit of the reading and after selecting, press «*» button.

5. Now, the 1’s digit in the screen is flashing. Press the «▲» and «▼» button to select the value. The value you select is 1’s digit of the reading and after selecting, press «*» button. Here, the whole calibration operation has been finished.

6. If the temperature still has departure, you can repeat calibration in accordance with the above steps.

7. When inputting calibration temperature, if the value of calibration temperature is error and the station have protection function that is after inputting the calibration temperature and press «*» button, the 100’s digit of display temperature will flash. Here, please re-input the value.

Suggest test the tip’s temperature with 191/192 thermometer.

If the soldering station is locked by password, it will not be able to calibrate the tip temperature and you must input the right password.

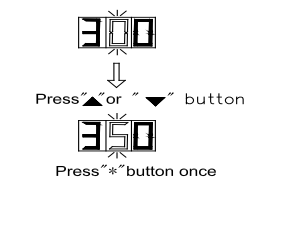

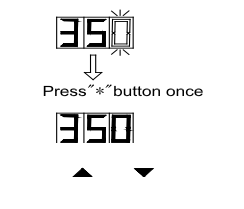

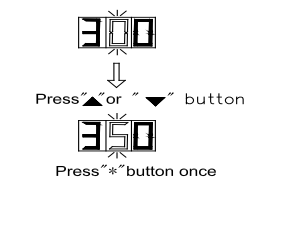

For example: When the displaying temperature is 400°C, input the calibration temperature 350°C.

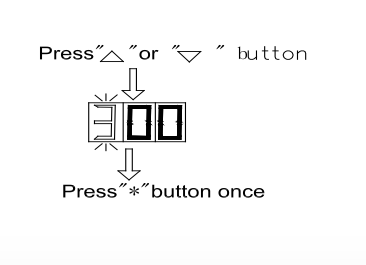

1. Press «*» button not to loosen and press the «▲» and «▼» buttons simultaneously, the soldering station enters into calibrating temperature mode. Here, the hundreds digit in LCD is flashing. This indicates that the station is in temperature calibrating mode and that the hundreds-digit can be adjusted.

2. Select the desired value for 100’s digit. Use the «▲» and «▼» button to change displayed value as follows.

→1 ↔ 2 ↔ 3 ↔ 4 ↔ 5 ←

Press the «*» button when the desired value is displayed. This will cause the middle digit (the tens digit) in the display to begin flashing.

3. Select the desired value for the tens digit. Use the «▲» and «▼» button to change displayed value as follows.

→ 1 ↔ 2 ↔ 3 ↔ 4 ↔ 5 ↔ 6 ↔ 7 ↔ 8 ↔ 9 ↔ 0 ←

Press the «*» button when the desired value is displayed. Here, the right digit (the one digit) will begin flashing to indicate that the one digit can be set.

4. Select the desired value for the 1’s digit. Use the «▲» and «▼» button to change displayed value as shown above for the tens place selection. Press the «*» button. Here, pressing the «*» button to enters the setting temperature into the internal memory.

Setting and Operating the Soldering Station

Iron Holder and Sponge

- Dampen the small cleaning sponge with water and then squeeze it dry.

- Place it in groove of the iron holder base.

- Add a little water to iron holder. The small sponge will absorb water to keep the large sponge around it wet at all times.

- Dampen the large cleaning sponge and place it on the iron holder base.

Note: If the sponge becomes dry during working, add appropriate water.

Connection

- Connect the connector of the handle cord to the socket behind the unit. Take notice of inserting position about connector.

- Place the soldering iron in the iron holder.

- Insert power plug into grounded power socket.

- Turn on power switch.